Die Manufacturing

We contribute through superior technical strength and technology,ultra-fine processing.

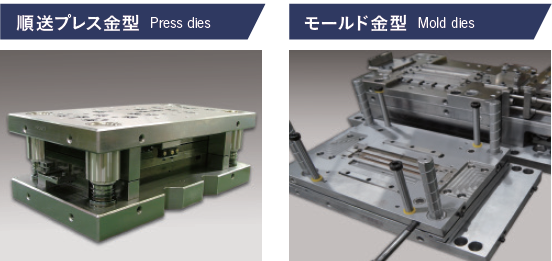

The origins of SUZUKI lie in die manufacturing. The Company deploys CAD in all phases of production of press dies, which produce metal products, and mold dies, which make plastic parts. CAD is involved in all phases of production at SUZUKI, from design of CAD data to material procurement and creating programs for machine processing.

An important feature of Hitakihara Plant is an environment that supports the formation of a cooperative system linking technology and manufacturing. This cooperative system is vital to SUZUKI’s delivery of high-quality products.

Through the relentless pursuit of precision and proactive capital investment, SUZUKI has achieved precision to within less than 0.001mm in its finished dies.

Supporting that precision is none other than the technical capabilities of SUZUKI’s outstanding technicians.

Processing in the field of high-precision components requires exhaustive knowledge and experienced technique.

By fusing creative design that understands customer needs with state-of-the-art processing equipment and superior skills, SUZUKI achieves processing at the ultrafine level.

Headquarters Plant

SUZUKI’s headquarters is in Suzaka, Nagano Prefecture. Here SUZUKI maintains head-office functions, such as sales and administration, and a plant, which produces the Company’s mainstay precision dies.

SUZUKI’s headquarters is in Suzaka, Nagano Prefecture. Here SUZUKI maintains head-office functions, such as sales and administration, and a plant, which produces the Company’s mainstay precision dies.